Oil Field Equipment

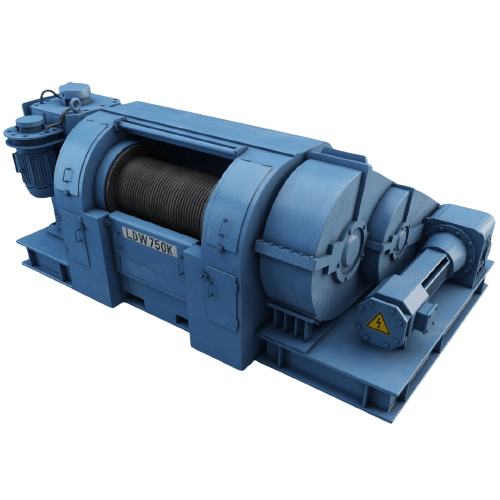

drawworks

repairs and replacement

- retrofit with hydraulic disk brakes

- independent rotary drive

- replacement of chains

- replacement of seals and bearings

- repair of draw works housing

parts

- stuffing box parts

- brake parts

- air and water parts

- replacement of bank brake system

- replacement of greasing/oil system

- replacement of locking system

- repair/replacement of rotary counter shop

- repair/replacement of brake water cooling system

travelling blocks

- unique offers size range from 200 tons to 500 tons

- unique also offers custom engineered traveling blocks for special application, designed and rated with API standards

- traveling equipment can be provided with third-party certifications: ABS, DNV and TUV-SUD

hoisting sheaves

- unique sheaves are available in sizes that range from 12" to 72"

- the bore can be made to accommodate tapered roller bearings, bronze bushings, snap rings as per customer specification.

- unique manufactures sheaves as per the industry standards, such as API 8A & API 8C.

- unique sheaves are flame hardened to a minimum 35 HRC an each bore is concentric to the groove.

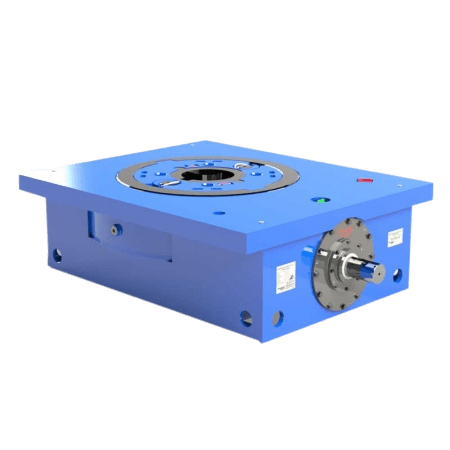

rotary

- unique offers a complete line of drilling rotary table that range from 17" to 60½".

- unique rotary table are fabricated from special grade steels for cranes with heavy duty main thrust bearing and precision machined spiral bevel gear, which results in superior strength, toughness and durability.

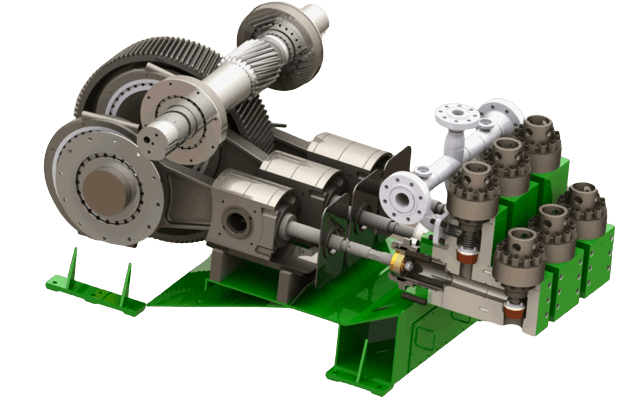

mud pump repairs and retrofits

- spares for mud pump gear end and fluid end

- conversion from chain drive to belt drive

- repair of mud pump housing.

- replacement of:

- lubrication and flushing system

- chains, bearings and oil seals

- shell and tube type heat exchanger

spares

piston hub

piston hubs are manufactured from AISI 510 heat treated forged alloy steel, machined on modern CNC lathe to exact dimensions. they meet all API tolerances and different temperature applications. available from 3″-8″ in series a.k.b and l with types of duplex and triplex.

piston rod

a full line of piston rods for various pumps are made with alloy steel through thermal refining treatment resulting in excellent mechanical characteristics. available in duplex and triplex.

piston

pistons are made with tough and durable rubbers for all pressures. available in single and double acting in variety of sizes for most pumps.

mud pump liner

liner is designed to fit most mud pump pipes. both duplex and triplex available in hi-chrome iron liner, chrome plated liner and hardened steel liner combining with state of the art manufacturing. unique liners can withstand mud pressure up to 9000 PSI. the life of our hi-chrome liners generally reach a level of more then 8000 Hours.

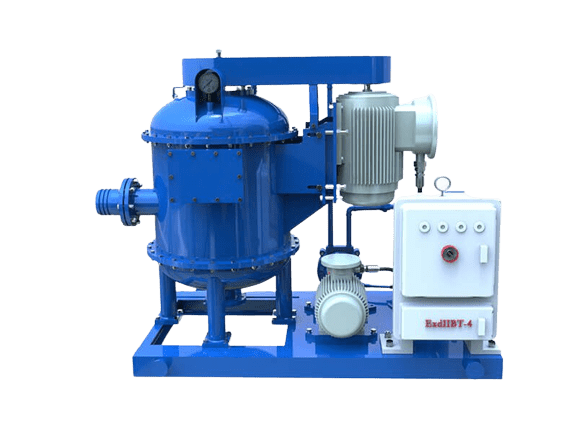

vaccum degasser

- unique degassers have a relatively more efficient vertical tank design than traditional horizontal degassers, offering more than 200% surface area compared to conventional designs.

- this enhanced capacity facilitates in reduction in: vessel size, tank space requirements, unit weight and reconfiguration of pit arrangements.

- a vacuum pump, capable of pulling 29" HG, draws mud into the degassing chamber, where reduction in pressure causes gas bubbles to surface from the fluid more rapidly.

- a stacked, corrugated fiberglass leaf arrangement and multiple feed ports provide higher fluid impact, thinner layers of mud dispersion, and greater turbulence for more efficient gas removal.

- unique degassers offer convenient access to the leaf assembly and float mechanisms (without having to remove the vessel lid) through an oversized access door. this feature significantly reduces downtime and maintenance costs compared to other units.

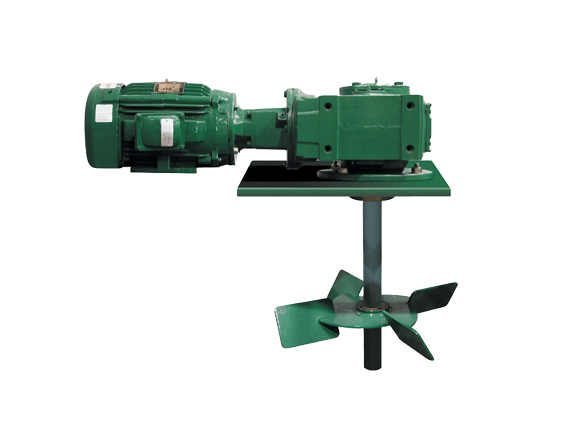

mud agitator

- unique mud agitators include an explosion-proof, "motor, reduction gearbox (helical-bevel for horizontal agitators or all helical for vertical units), impeller, and shaft with assembly bushings." motors range from 5 to 30 HP and may be supplied in several power configurations.

- fixing the motor directly inline to the gearbox prevents misalignment that can result in premature bearing failure and provides 95 percent efficiency in power transfer to the impeller.

- this improved design surpasses standard worm drive gear assemblies by 30 percent, allowing unique agitators to do the same work at far less horsepower. by unitizing the motor and the gearbox, weight and space requirements are reduced.

- horsepower, mechanical configuration, impeller diameter as well as shaft length are customized to tank dimensions and maximum mud weights. available horsepower ratings are: 5, 7.5, 10, 15, 20, 25, and 30.

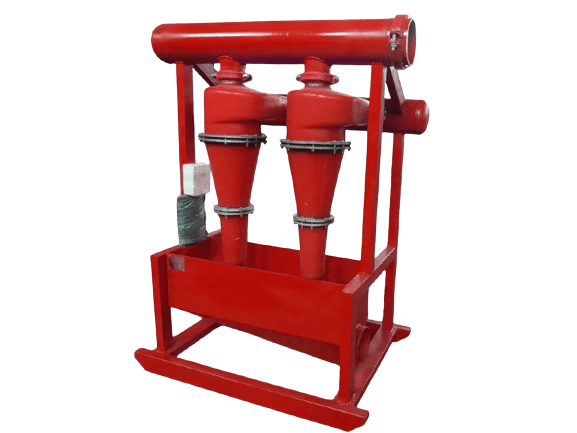

desander

- unique desander is compact, designed for separation of solids from fluid such as the drilling mud also referred as drilling fluid.

- unique series desander is the second phase solid control equipment in well drilling, the general cones are 8", 10" & 12" .

- unique cones are made of 100% polyurethane or abrasion-resistant alloy material,perfectly suitable to match Desander and desilter.

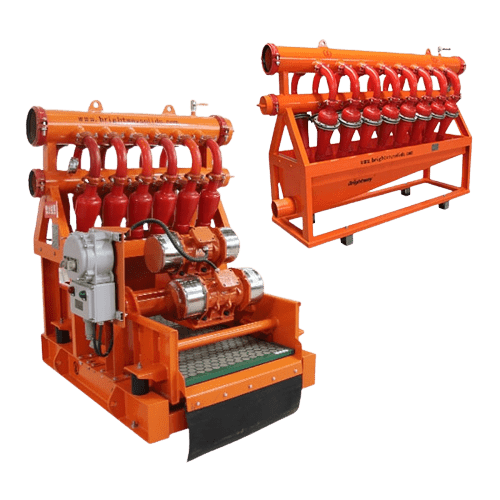

desilter

- unique series desilter is the third phase solid control equipment to treat the drilling fluids.

- according to the size of the cone diameter, they are divided into desander and disilter. usually, the cone diameter less than 6" is called desilter.

- desilter are used as the third control equipment in drilling operation.

- Unique commonly uses 5" cones to separate solid phase particles of size 15-47 microns. However, we select group of cones into desilter based on customer requirement and capacity.

mud gas seperator

- unique mud gas separators are designed for use where drilling is likely to encounter large volumes of gas.

- unique mud gas separators are designed in accordance with ASME Sec div.1 and NACE standards.

- the unique design is especially advantageous in sour gas environments or, when drilling with an underbalanced mud column.

- the mud gas separator is used primarily to separate and safely vent large pockets of free gas from the active mud system.

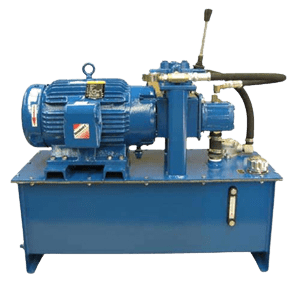

hydraulic system

- unique designs and manufactures wide range of hydraulic systems for various applications which include critical application like snubbing system for mast raising.

- we can undertake manufacturing of any type of hydraulic system as per customers requirement.

hammer uniouns

hammer uniouns

- hammer unions range in size from 1" to 12"

- maximum working pressure of 15,000 PSI

- manufactured from forged steel

- ASTM- 105 unions > 6,000 PSI

- AISI 4130 for unions < 6,000 PSI

pressure relief valves

- available from 2" to 8"

- available upto 5000 PSI

- newly designed subs and seals make for longer-lasting valve life for b/m2 valve

- precision machined valves allows for accurate setting

- advanced seal offers resistance against the most abrasive drilling

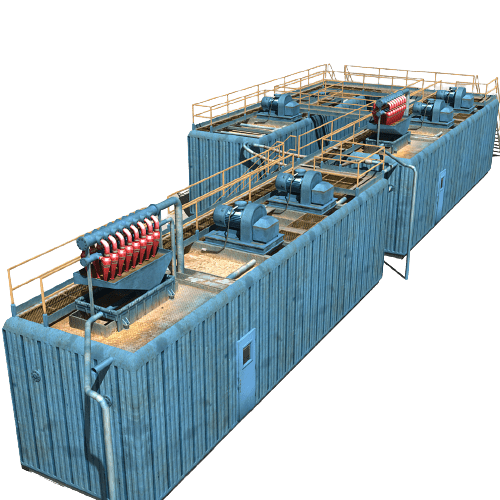

mud circulating system

- unique design concept of mud tanks consider two opposing criteria's i.e., the transport tanks has to be small and light, At the same time,they have to be strong and rugged enough to handle mud with a specific gravity of 24 PPG

- unique can design and manufacture mud tank/water tank and oil tank according to customers requirement

- the quality of welding seams, surface treatment and special paint is essential features of unique tanks. we have designed standard mud systems for various sizes of drill rigs

- we can use material from selected manufacturers based on our experience so that the quality requirements are always fulfilled

diesel systems

- it consists of fuel tanks having total capacity as per customer requirement. suitable diesel pumping unit is also provided with filters and associated piping.

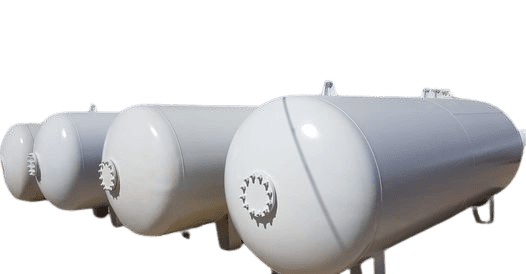

air system

- it consists of 2 electrical driven compressors with working pressure of 150 PSIG. free air delivery 200 -250 CFM

- motor hp100. one diesel engine driven cold start air compressor . air receivers of adequate capacity and quantity are also provided.

- a suitable air drier unit is also provided with the air system.